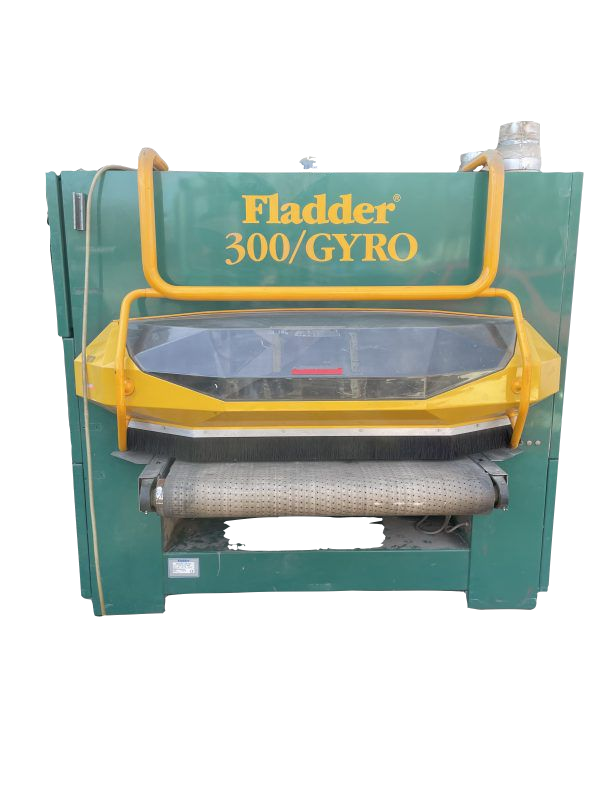

Fladder SC

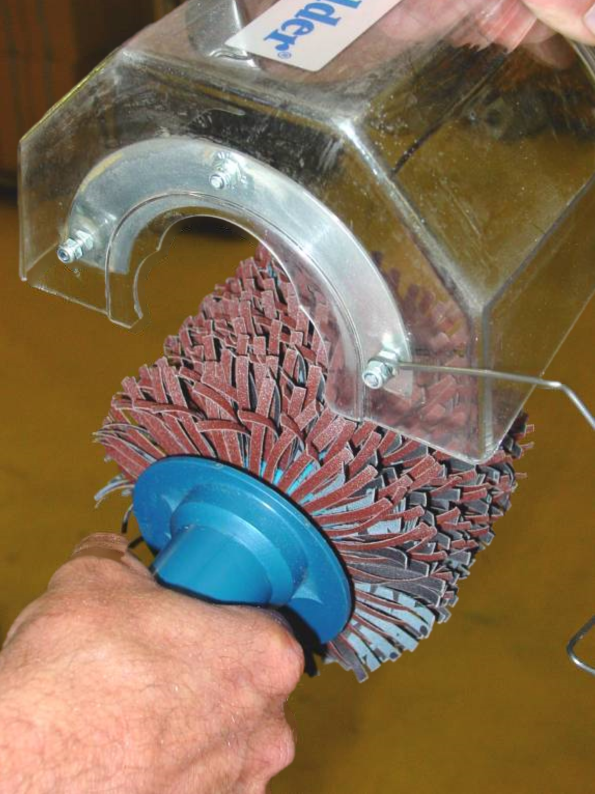

Ideal for finishing workpieces that are often difficult to hold while finishing

Shaped plywood parts, furniture components, assembled chair parts, toilet seats, machined aviation parts, automotive parts, and curved plastic parts are all suited for this machine

During the process, workpieces are held firmly in place by custom-made fixtures

- Machine Height 2210 mm

- Working Width 1200 mm

- Lock-It Spindles and Length 6 x 100 x 350 mm

- Dust Collecting 2500 m3/t

- Net Weight 1700 kgs

FLADDER

Based out of Denmark, Fladder manufactures latest models of deburring, denibbing and finishing systems. They develop solution to benefit and increase the efficiency in the production process. Their product line consists of automated machines, Special machines, hand held machines and other accessories. Their application ranges from wood industry to metal and many other industries that are in need of their offerings